Highway and Bridge Construction Drilling (Completed – 2009-2014)

David Rempel, MD

University of California, San Francisco

San Francisco, CA

Ph: (510) 665-3403

[email protected]

Research Team

University of California at Berkeley Ergonomics Program; California Department of Public Health – Occupational Health Branch; Laborers International Union of North America (LIUNA); RM Harris; PCL Construction; Cahill Contractors; Alten Construction; WebCor Builders; AGC-California; DustControl Inc., and Atlas-Copco.

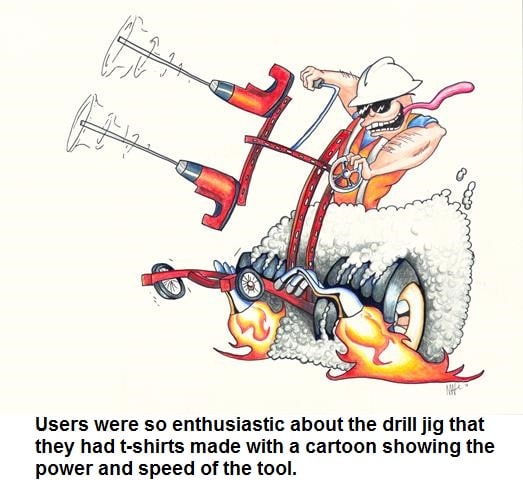

- A universal saddle that accepts large electric hammer drills and pneumatic rock hammers,

- A more reliable remote on-off switch,

- A new design that allows the drilling arm to be set to any drilling angle, without cumbersome removal and resetting of bolts, thereby reducing bending and reaching during drilling,

- A new bearing system that makes the jig easier to use and more robust,

- A drill saddle design that allows using two drills simultaneously.

Equally important, Rempel and Barr have enlisted the drill jig in the war against silica hazards. Tasks like dowel drilling and overhead or lateral drilling in rock or concrete can generate significant amounts of dangerous airborne crystalline silica. Workers who inhale the particles are vulnerable to silicosis and related respiratory problems, an occupational health concern severe enough that OSHA has proposed a new rule requiring more stringent workplace controls. To reduce exposure, Rempel and Barr have incorporated a new dust capture system on the drill. Dust control is achieved by one of two methods; the most common is a dust shroud over the bit that attaches to the jig. A new innovation from Hilti, using a hollow bit with a vacuum port, was deployed on the McCarthy project. The vacuums are mounted on the jig for ease of movement.

- Using feedback from laborers and electricians who used the jig, the team improved its design with a universal drill saddle, an improved remote on/off switch, and a new method for rapidly adjusting drilling height and angle.

- Bay Area contractors have put the drilling jigs to use on seven commercial construction sites, including a seismic retrofit of the Bay Area Rapid Transit (BART) towers.

- New overhead drill jig heads allow the option of drilling two or four holes simultaneously – one contractor successfully used the dual drill jig to install miles of electrical conduit in half the expected time.

- The team has presented findings to four national and local contractors’ health and safety meetings, three union health and safety meetings, six scientific conferences and in an article published in the Journal of Occupational and Environmental Hygiene.

- A local manufacturer, Ergomek.com, is now producing a commercial version of the jig called the DrillBoss.