Adoption of Innovations to Minimize (AIMS) Exposures to Dusts and Fume in Construction (Completed – 2009-2014)

Pam Susi, MSPH, CIH

CPWR, New Jersey

Ph: 301-717-7568

[email protected]

Research Team

Sergio Caporali Filho, PhD, CIH, University of Puerto Rico; Colden Corporation; Michael Cooper, MPH, CIH, CSP; Mike Flynn, ScD, CIH, Univ. of North Carolina; Mark Goldberg, PhD, CIH, Hunter College Emeritus; Bob Herrick, ScD, CIH, Harvard School of Public Health; John Meeker, ScD, CIH, University of Michigan; Marc Weinstein, PhD, Florida International University

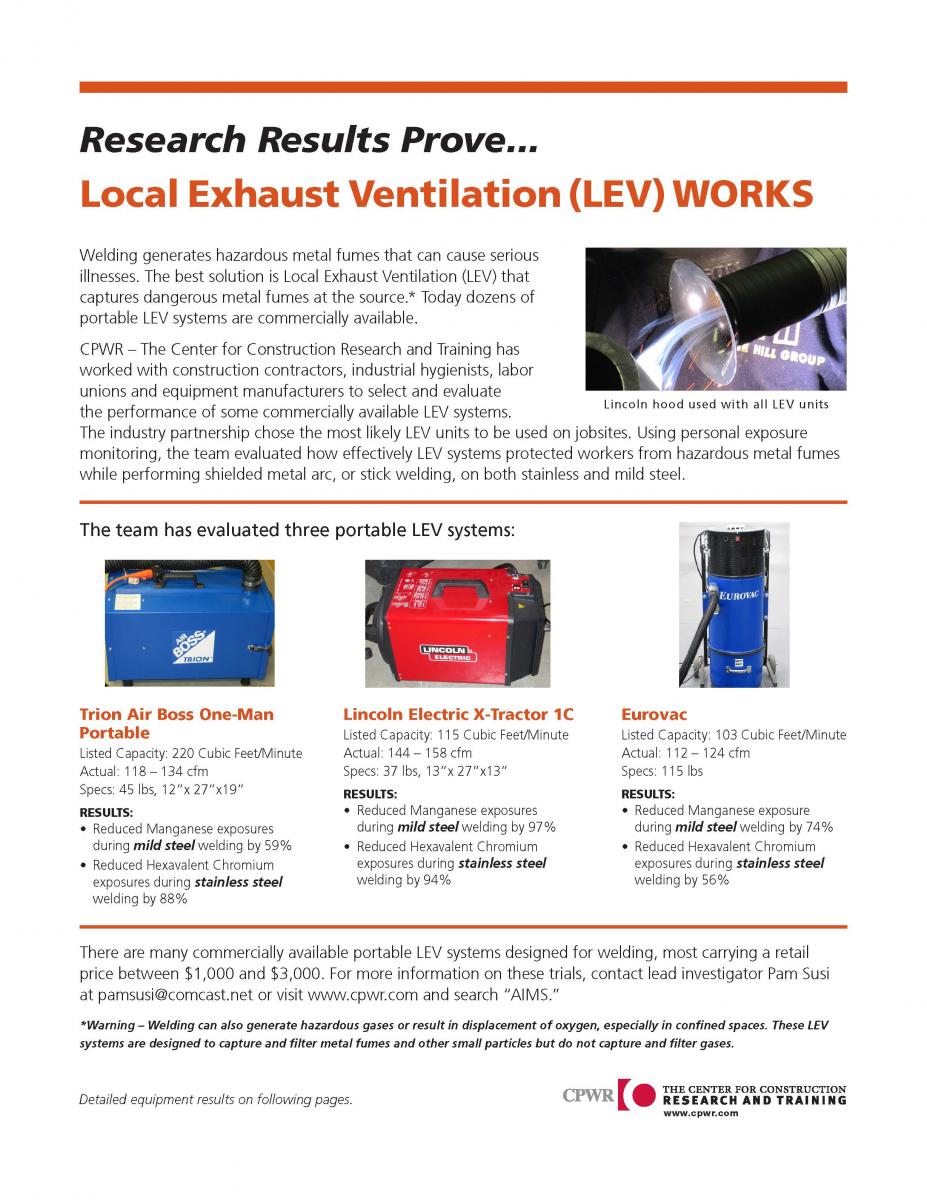

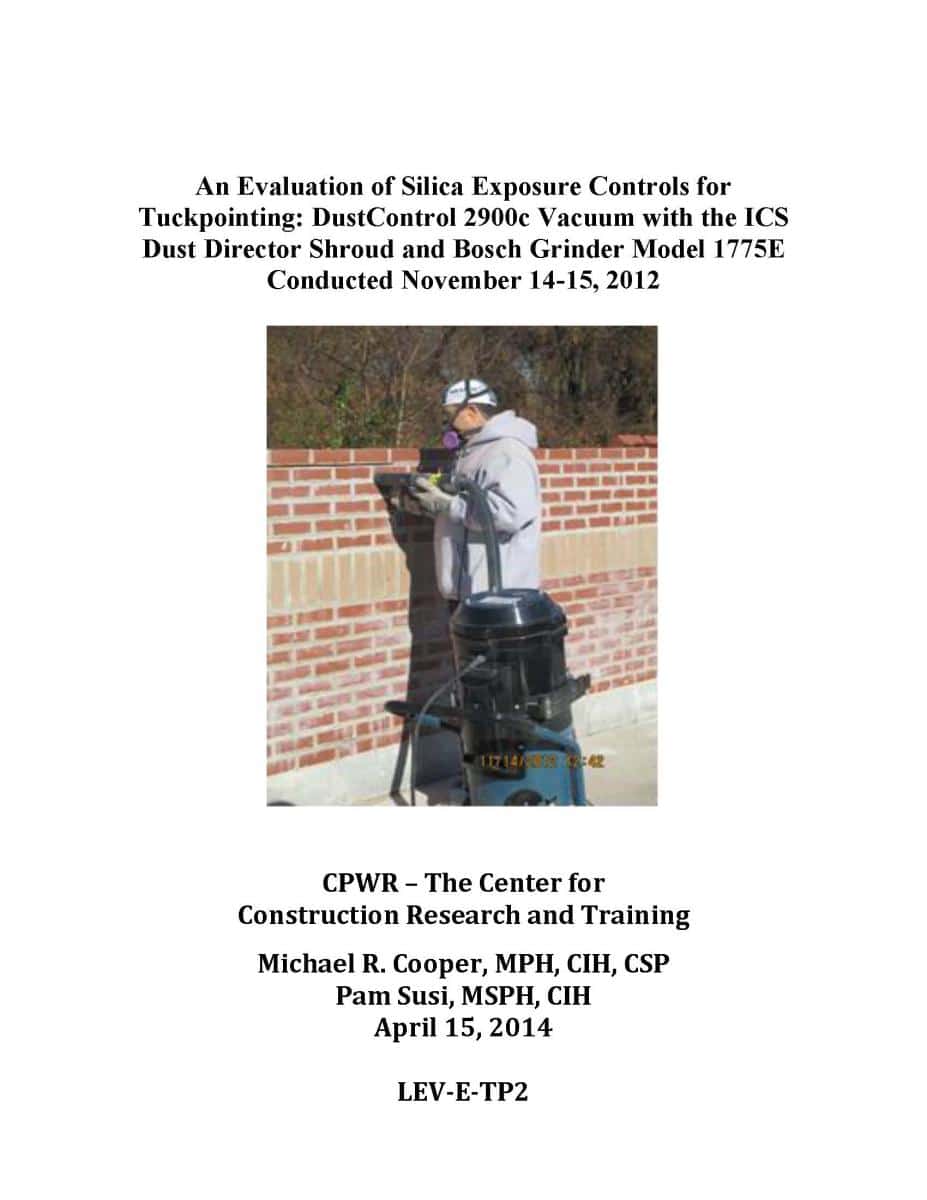

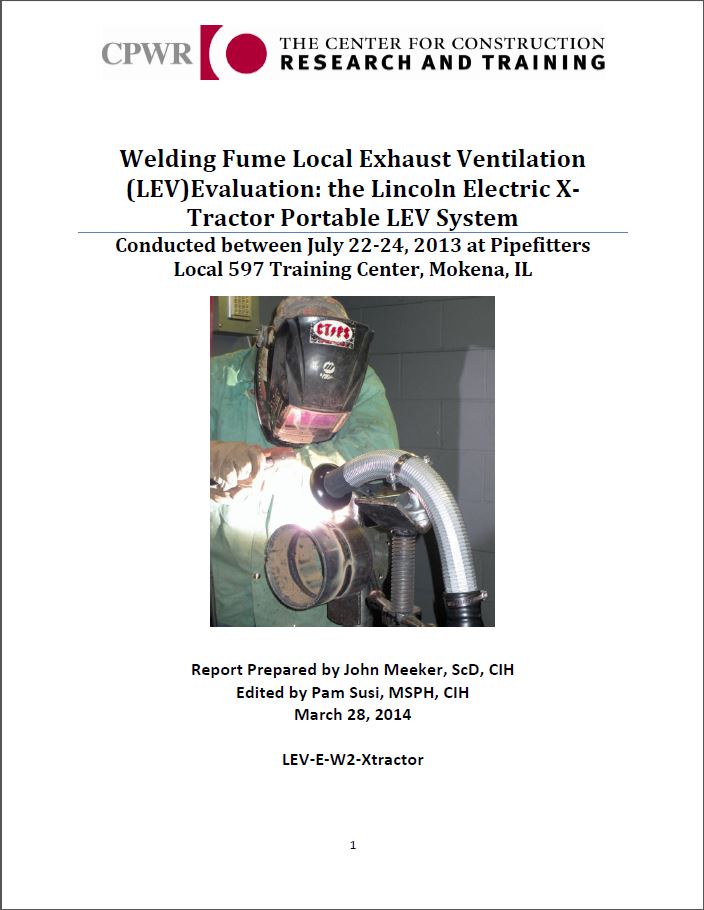

This project actively engaged industry partners in the selection, diffusion, and promotion of LEV systems for welding fumes and tuck-pointing. This proved to be an extremely successful approach. All of the LEV systems evaluated proved to be effective based on our performance criteria. Furthermore, since the systems evaluated were selected by workers and contractors from the trade specialties that would typically use them, our research provided evidence of the availability of effective and practical engineering controls.

Research related to training on correct use of LEV for welding revealed an initial weak baseline understanding of the hazards associated with welding fumes and the preferred and correct control methods. This was reflected in quizzes, questionnaires, and in measured personal exposure levels when welding with LEV prior to training. After training, personal exposures to welding fumes dropped substantially – the ultimate measure of effectiveness. In addition, attitudes and beliefs favoring future correct use of LEV were cultivated.

Finally, our research served as a catalyst and as evidence for industry and government to use in improving control technology design and creating new policies likely to increase use of effective engineering controls. Our case study research demonstrated that at least in a major metropolitan area like Chicago, local approaches to promoting use of engineering controls may go further more quickly and more completely than sole reliance on OSHA. Local environmental regulations and major public users in Chicago played a major role in stimulating the early adoption of LEV for tuck-pointing. In just four years, we made remarkable progress with regard to identifying, evaluating, and promoting use of effective control technologies for welding and tuck-pointing in construction and expanded our research focus to include the emerging field of nanomaterials in construction.

- The Philadelphia School District used CPWR’s Model Silica Specifications and developed effective guidelines and regulations in Philadelphia – the fifth largest city in the U.S.

- The OSHA Directorate of Training and Education distributed Model Silica Specifications to industrial hygienists taking OSHA safety classes.

- A story about and link to the Model Specifications were included in eNews on the NIOSH website, which has approximately 60,000 subscribers.

- International dust control manufacturer, Pullman-Ermator, designed, patented, and now sells a new “Dust Hood” for grinders, as a result of our 2013 evaluation of their vacuum system.

- Twenty-two presentations were given to industry, occupational health professionals, and government.

- Two articles were published in the Annals of Occupational Hygiene, and the Journal of Occupational and Environmental Health.

- Two articles were published in the trade publications the AIHA Synergist and the Mechanical Contractors Association of America Reporter.